The path planning algorithm is an essential part of the palletizing software. It calculates the optimal movement from the pickup position to the pallet position (MoveTarget). These calculations are performed dynamically when the robot moves one or more boxes from the pickup to the pallet position.

Robot movement when placing box: Pickup position → Box free height → Smart Exit → Extra waypoint → Approach Position → Target Position |

Robot movement when travel back to grab new box: Vertical exit point → Extra waypoint → Smart Exit → Above pickup -->Pickup position |

The path starts with a position above the pickup point to ensure the gripper moves vertically down against the box surface. After picking the products, the robot moves vertically up until the box is removed from between the side guides. Depending on the current pickup and target positions, this is followed by one or more waypoints in order to move and rotate the box(es) without collision to the robot base or the existing boxes on the pallet. The approach position is the last waypoint in the proximity of the final target position. The robot uses lower acceleration and speed from the approach to the final target position to improve the pallet accuracy.

Note: To ensure a smooth palletizer experience, all inputs of the production line should be carefully measured. |

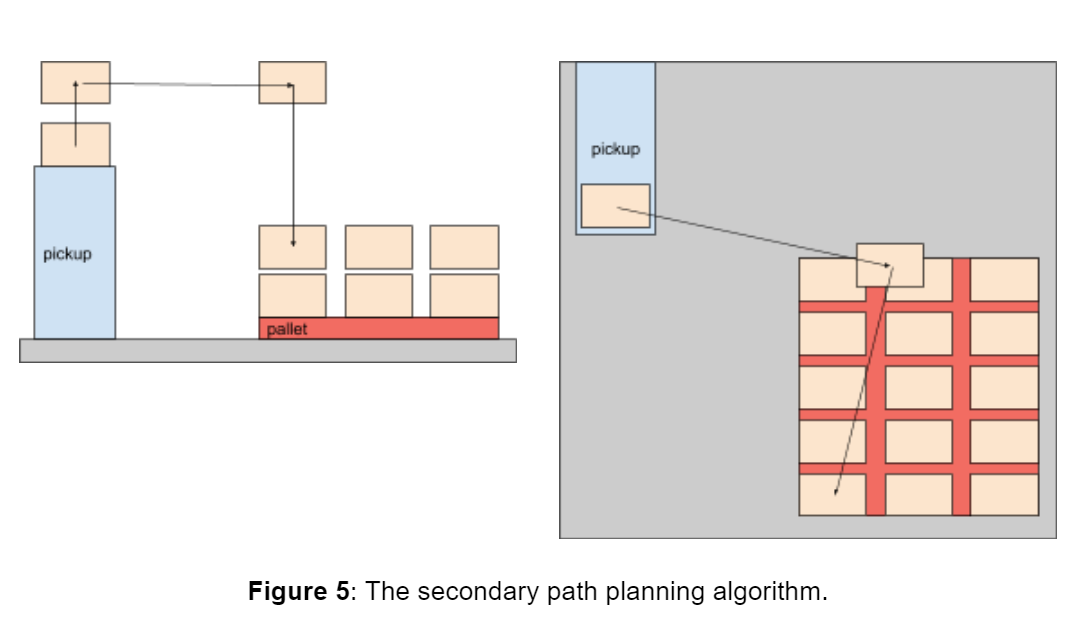

The goal of the primary path planning algorithm is to move the box on a linear path whenever possible, see Figure 3 and Figure 4. After the box is taken from the pickup position, the algorithm tries to find one waypoint - called smart exit position - from where the shortest, direct linear movement is possible.

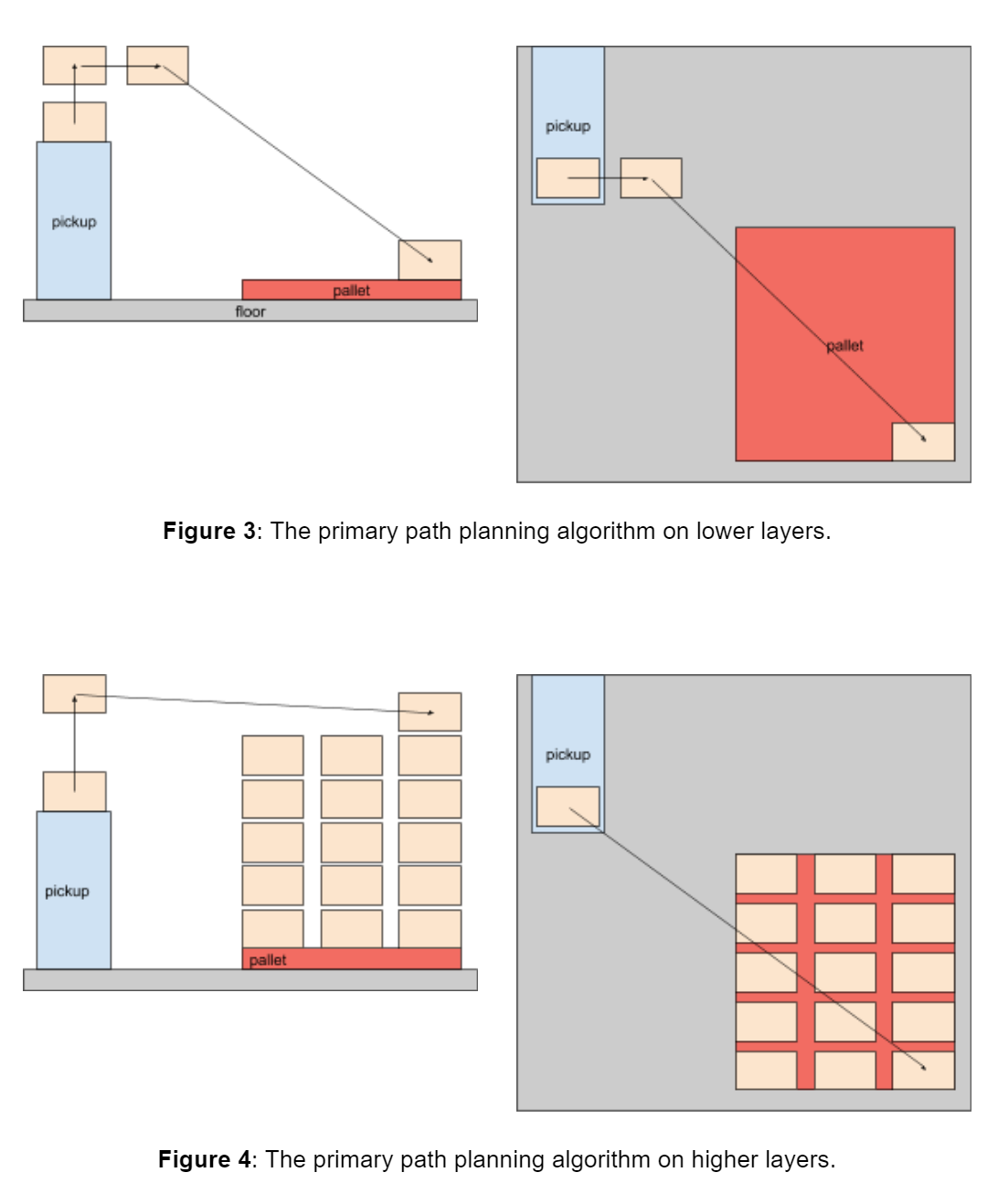

The secondary path planning algorithm is effective when the primary algorithm does not find a smart exit position from where a direct linear movement is possible. In this case, the box is moved above all other boxes, and then lowered vertically to the target position, see Figure 5. This path is normally longer than a direct linear movement, and hence more time demanding.