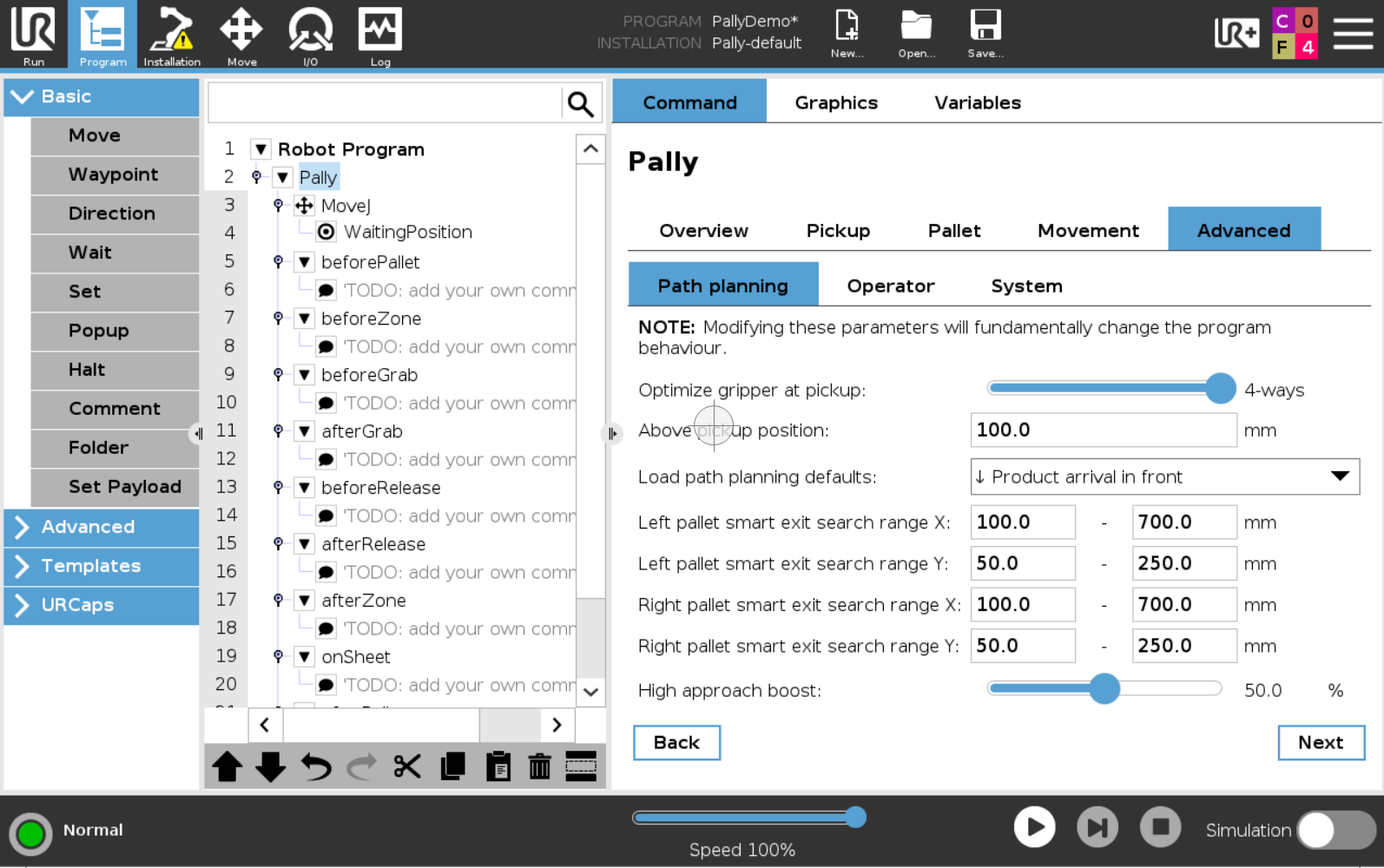

You can select different gripper orientations at pickup to have better reach for the box onto the palletIn order to get better reach or performance, the program can automatically recalculate and use the gripper rotated by +90, -90, 180 degrees at the pickup position. This may be necessary to reach the pallet corners or avoid collision with the base frame.

The allowed rotations can be configured. You can instruct the optimizer to enforce the default orientation, choose between forward and backward, or choose between forward, backward, left, or right. Pally will calculate the best optimize optimized grip for each box, if enabled.

Optimize gripper options: NONE - 2-WAY - 4-WAY

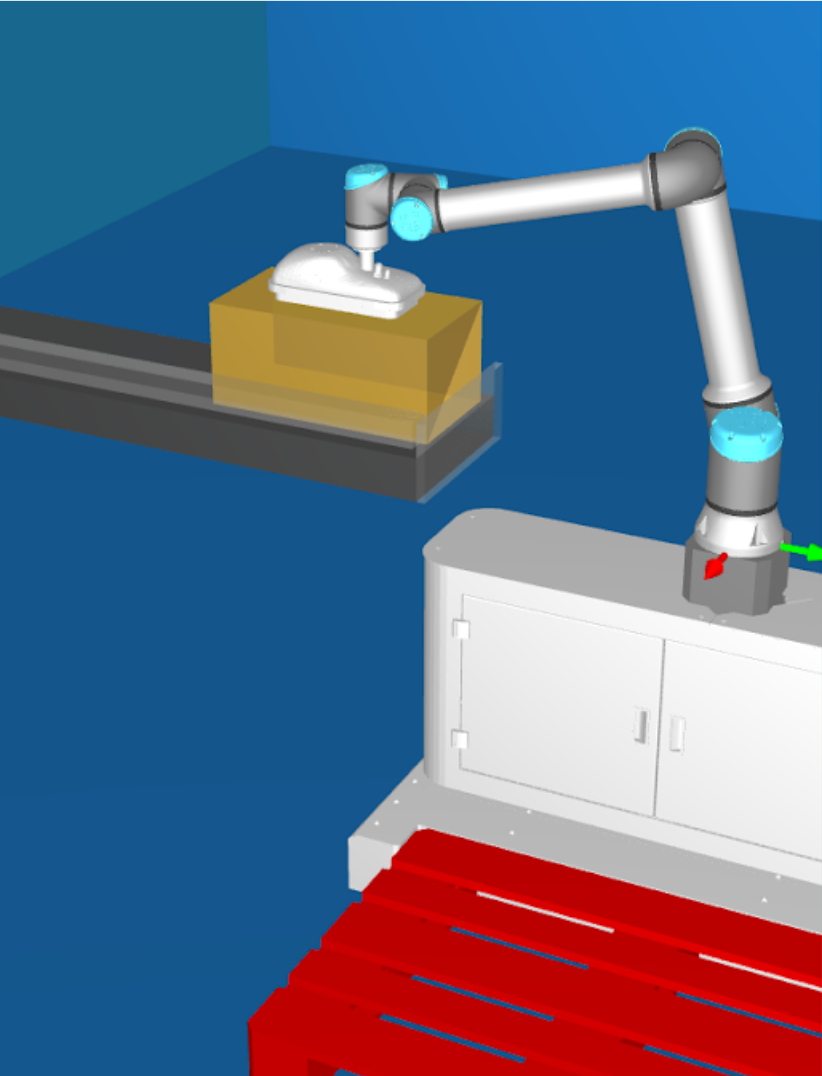

None: InFrontVisual representation of the different gripper rotations at pickup

| Info |

|---|

Note: the rotations are relative to the default calibrated orientation (forward) |

Gripper optimization settings can be selected in Program / Pally / Advanced / Path planning

None: forward (the gripper direction at the calibrated pick position)

2-Way: InFront forward and InBackbackward

4-Way: InFront forward, backward, InLeftleft, InBack and InRightright

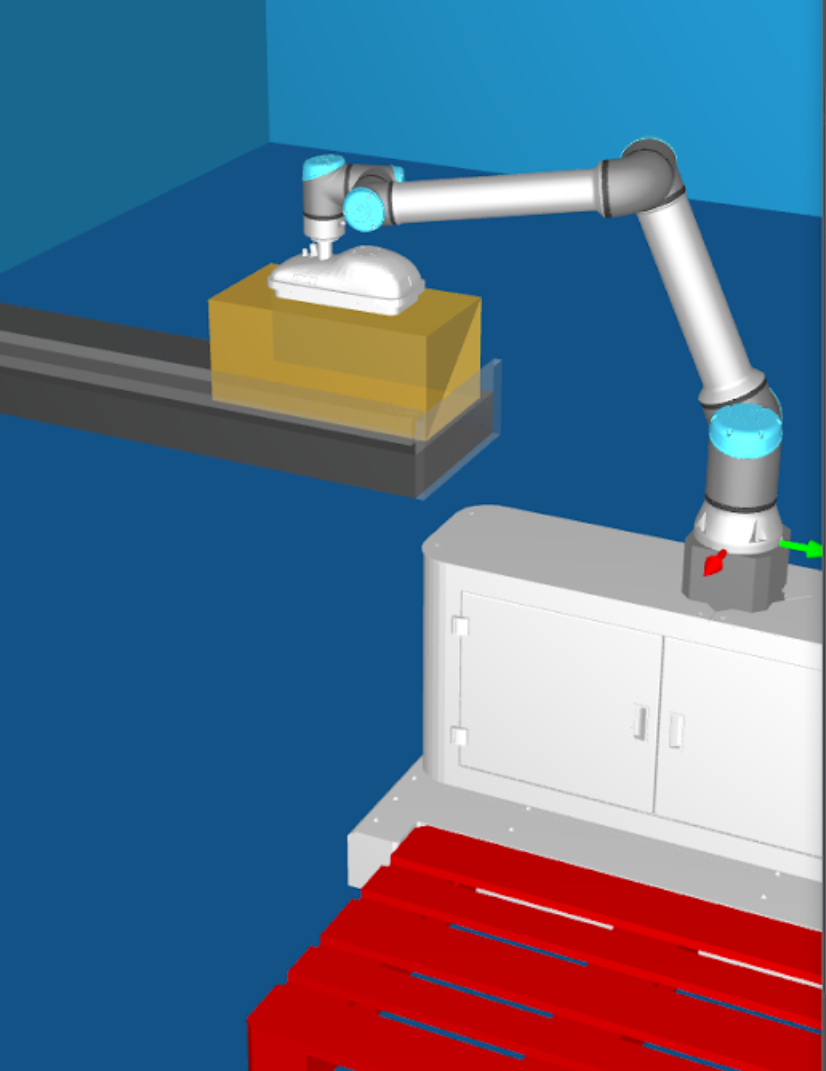

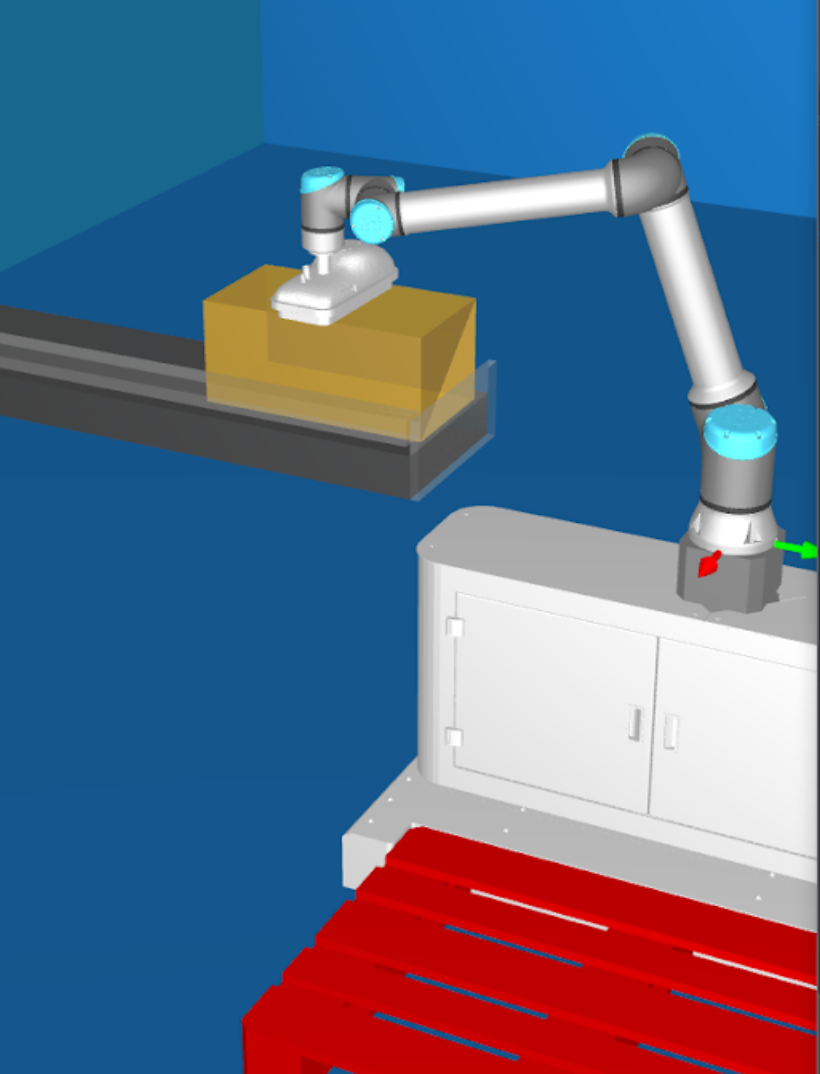

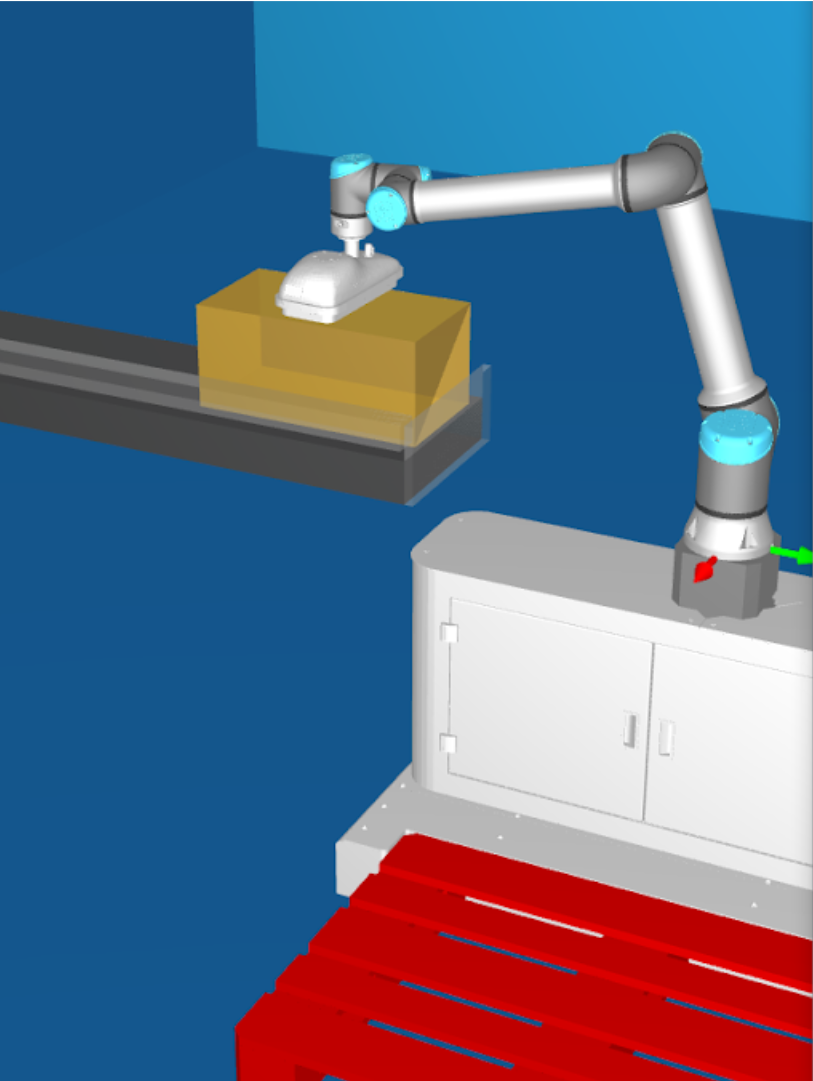

Visual representation of the different optimize gripper options

InFront

InBack

InLeft

InRight

Info

The first element is the number of allowed rotations n,

The next n elements are the allowed rotations in degrees.

Example:

| Code Block |

|---|

rf_grip_rot = [3, 0, -90, 90, 0] |

This will tell the optimizer to choose a gripper rotation between forward, left, and right (backward is not allowed)